Simple Steps When Choosing Hardwood Floors

Hardwood floors are not only a beautiful addition to your home but they may also increase the value of your property. If you are considering installing hardwood floors in your home, the choices seem endless: unfinished, pre-finished, laminate, engineered, plank, strip, stained or natural, satin or gloss finish and more… Let’s break this daunting task down into a few simple steps and considerations when choosing wood floors.

Step One – Choose the Type of Flooring

Unfinished Solid Wood

After installation, bare wood flooring strips or planks are sanded, sometimes stained, and finished with three protective polyurethane coats. When choosing an unfinished product you are not limited. You have plethora of options: reclaimed or antique cuts of wood, intricate patterns or designs with exotic woods. The choices are abundant.

A solid wood floor can be sanded 7-8 times depending on wear and tear.

Pre-Finished Hardwood Floors

Installing a solid pre-finished wood floor is a way to forgo the sanding, staining, and finishing process. This is a good alternative for those with allergies or other health related issues.

Pre-finished hardwood floors have the color and finish already applied in the factory which makes the installation more time consuming as additional care needs to be taken when fitting the boards.

One drawback to pre-finished wood flooring is that the flooring is usually produced with beveled edging which can trap dirt and dust.

A properly manufactured solid un-finished or pre-finished wood floor can be sanded up to 7 –8 times depending on wear.

LAMINATE FLOORING (not a hardwood product):

Is compressed sawdust that is glued together. The surface of a laminate floor is a photographed image of a finished hardwood floor. A laminate floor is not a solid wood flooring product and if damaged or worn it becomes a throw away product.

ENGINEERED WOOD FLOORING:

Engineered wood floors are comprised of layers or plies. The more plies, the more stable the flooring. Thickness can range from 5/16 inch up to 3/4 inch, having 3-11 layers. The wear layer is the top section and the thicker this layer hence the more times the floor can be sanded. Wear layers vary depending on the manufacturer. Engineered wood floors can be finished onsite after installation or can be pre-finished in a factory.

Step 2 – Choose the Wood Floor Width and Length

The width of wood floors most commonly seen in homes is 2-1/4” to 3-1/4” but can vary. Boards can be as wide as 10” to 12”. The width a homeowner chooses depends on the style and atmosphere they choose to create in there home.

Wider width floor boards are often used for a rustic look or a new modern design. If you choose a wider board be mindful of relative humidity as gaps will become more prominent with seasonal changes.

Typically random lengths of floor boards are installed. The length of boards can vary from 1’ up to 7’ or 8’. The lengths used are dependent on the size of the room and the style a homeowner wishes to portray.

Step 3 – Choose the Wood Floor Grade

Plain sawn or flat sawn, is the most common lumber used today. It is readily available and the most cost effective.

Quarter sawn wood is often chosen for its straight grain pattern and dramatic flecking that provides beautiful design. In addition this type of wood is very stable, making it ideal to work with if fluctuations in relative humidity are a factor.

Rift sawn wood is often used in adjunct with quarter sawn lumber. Rift sawn wood has a linear grain pattern with no flecking. As with the quarter sawn wood, it is very dimensionally stable. Rift and quarter sawn woods are often a choice for installation over radiant heat or in areas that are moisture prone.

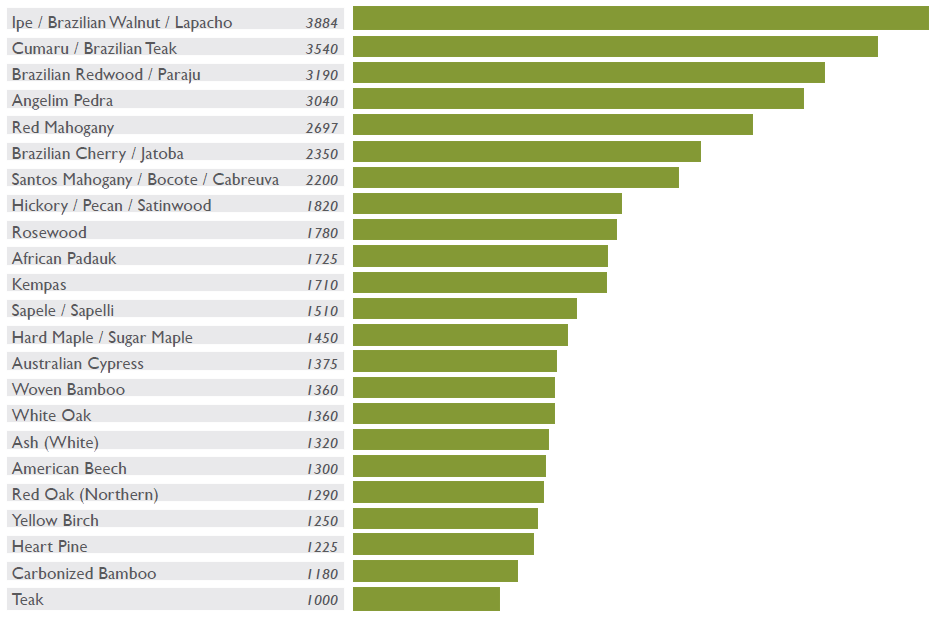

Something to consider: Durability and the Janka Scale

Durability of a hardwood floor comes into play when choosing flooring. The Janka Hardness Scale rating is the standard for the wood flooring industry in determining whether a given wood is suitable as a flooring material. The scale is a general guide when comparing species of wood flooring.

The majority of hardwoods and many softwoods are durable enough to withstand normal flooring traffic and use. Regardless of the Janka rating a floor will dent if not cared for properly.

Step 4 – Choose the Color

Nowadays an array of floor color choices are available for homeowners. Floors can be stained and or dyed to be dark or light or a shade in the middle. Undertones of gray, blue, yellow and red are all possible.

Step 5 – Choose the Finish Sheen and Water or Oil-based

Polyurethane is the protective top coating on your wood floor. There are three different sheens: satin, semi-gloss and gloss. Polyurethanes are either oil based or water based.

Oil-base polyurethanes are durable and cost effective. When applied it leaves the floor with a natural honey blonde tone which yellows over time.

Water-base polyurethane (Traffic by the Bona Company) is a clear finish with a low odor. The product is less durable than the oil finish and more costly. Water base finishes typically are applied after staining wood floors or where the yellowing effect is not desired. This products low odor makes it a popular choice in condo units or offices.

Other Considerations

When choosing hardwood floors there are yet more choices! Install floors on the diagonal to open up a space, borders can enhance the elegance of a living space, inlays can add detail and medallions are a way to show your unique style and character. If a special design or pattern is in your dreams discuss with your flooring contractor.